For cosmetic parts such as enclosures and housing. Prototype parts can normally be run on wood molds with as many as 50 pieces.

Plastic Injection Molding Infographic Streamline Plastics Plastic Injection Plastic Injection Molding Injection Molding

A male mold is generally less expensive than a female mold.

. Each process has some unique features and benefits that are often advantageous for a specific application. Air distribution Air distribution channels on the bottom of the mould have to be provided for perfect thermoforms. In order to better predict and calculate the mold flow system prior to practical manufacturing HongZu design team apply the CFD computational fluid dynamics technology to every mold we built.

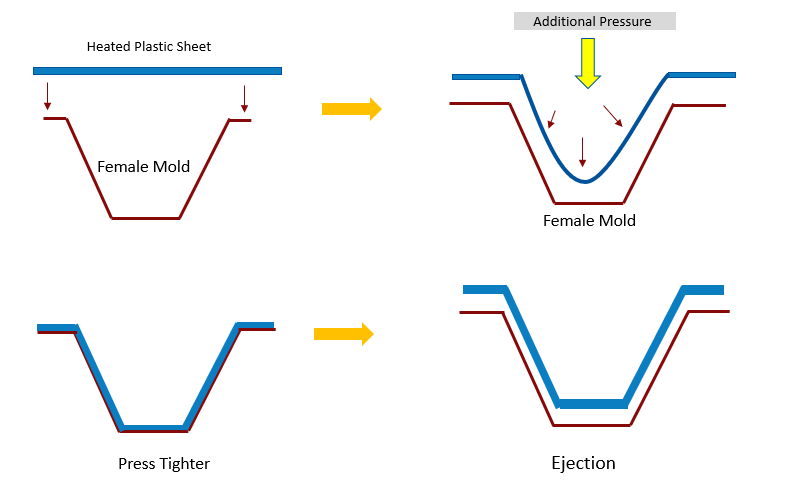

Introduction Thermoforming usually describes a process whereby a thermoplastic sheet is heated sufficiently to soften it and then cooled to become solid again after forming to the required shape. 300 x 400 x 40mm. The molded plastic parts are then trimmed and inspected for quality.

The maximum mold pressure for vacuum forming is under 15 psi. Uncoupled design except from the design equ ation for FR 12s and FR 21s and their correspondent DPs. Thermoforming covers all processes which involve heat to shape polymers.

Wagenknecht1 stated that technical terminology has not been standardised and. With a male mold the mold extends through the sheetline and clamp frame and the plastic is draped over the mold. Air distribution channels machined into a METAPOR mould could look as follows.

An inside corner on a female mold may be as tight as 164. In these instances the choice to manufacture with plastic thermoforming or. Tooling costs for thermoforming are significantly lower than tooling costs for injection molding.

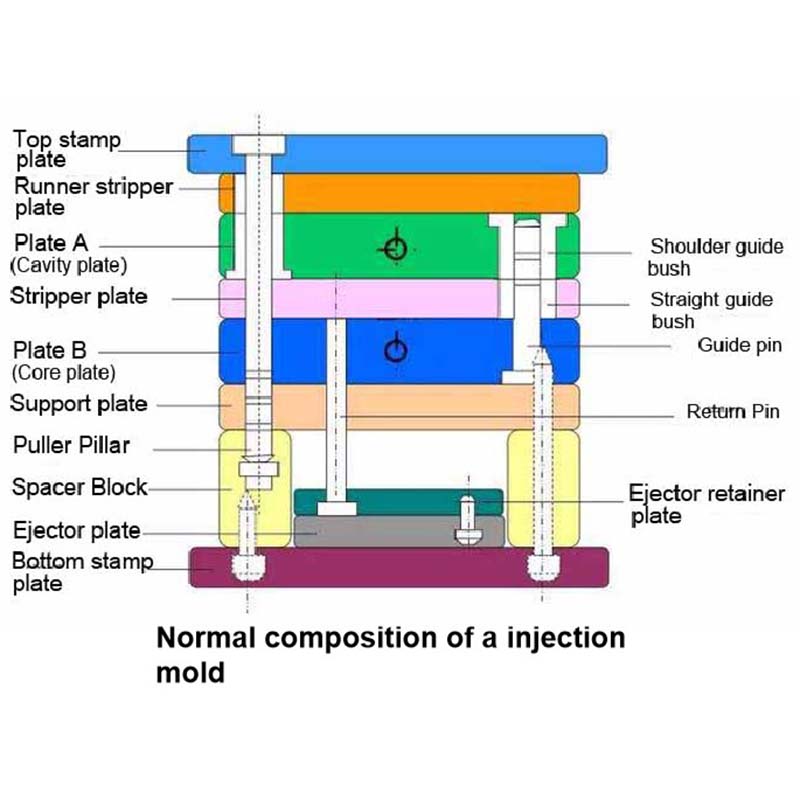

Cooling system is a core technique in mold efficiency. Design and Technical Injection molding and the plastic thermoforming process both have widespread uses in a long list of industries. Unformed part of the sheet are lost 31 Rate.

Mold pressures for pressure forming can range from 30 to 300 psi and requires tooling accordingly. Contact with the cold mold surface and the par Thermoforming is a process in which a flat thermoplastic sheet is heated and deformed into the desired shape. Distance from channel center to channel center.

The process of injecting compressed air 20-120 psi between two hot sheets thus forcing it to conform to the contour of each of two molds mounted opposed to each oth-er. If the part is large the mold may be cast aluminum. 300 x 400 x 40mm Size of distribution channel.

Thermoformed production molds are typically made from machined aluminum. WWWTHERMOFORMINGDIVISIONCOM Quarterly Thermoforming INSIDE. Female molds Male Molds.

The molding is then cooled before it is ejected from the mold using reverse pressure. Size of distribution channel. This combination provides us control over the mold design and the capacity to meet demanding delivery schedules.

Minimum draft angle for a Female mold is generally 2 degrees. 4 Part removed and CNC trimmed to specification. Thermoforming process is whether to use a plug male mold or a cavity female mold design.

2 Heated plastic sheet is placed over the mold face covered. Generally speaking amorphous materials like polystyrene ABS polycarbonate PVC and PVCAcrylic blends are easier to vacuum form. The sheet is pulled into the mold with a vacuum.

1 Sheet is heated to thermoforming temperature. Thermoforming particularly pressure forming is more cost effective for very large parts where the. Parts formed over a male mold will generally retain the texture and color of the extruded sheet so additional finish painting can be avoided.

Tolerances of a molded part. The individual design depends on size and geometry of the mould. In deciding between plastic thermoforming and injection molding for your next project there are several important factors to keep in mind.

1 Thermoplastic sheet is secured heated to forming temperature. Draft angles on a female mold can be less than on a male mold because the part shrinks away from the mold as it cools assisting in the part releasing from the mold. 3 Air is applied above the mold and vented below to form shape.

Request PDF Mold design and fabrication for production of thermoformed paper-based packaging products Paper-based packaging products are a. Thermoforming molds can be produced from a wide variety of materials depending on the size of the part quantity detail and dimensional accuracy required. Thermoforming is the heating of a plastic sheet which is then draped over a mold while vacuum is applied.

- 020 001 inin. Design guidelines for the thermoforming process 9 9 2. 9 INTRODUCTION continued Advantages Production parts can be run on relatively inexpensive aluminum or epoxy molds.

Once it reaches the right temperature the sheet advances to the form section. Good rule of thumb is a minimum of 3 degrees of draft on all surfaces perpendicular to base plate on the mold. In this guide we will focus on the vacuum forming and pressure forming processes.

15 x 5 mm. Other considerations when deciding on this fundamental design concept include location of thinnest cross section material shrink rates a. THE ADVANTAGES OF THERMOFORMING Thermoforming has many advantages over other plastic.

The following sketches show the most common procedures. The plastic hardens and forms the desired part. This critical decision is often brushed over in the literature yet has the greatest single impact on part wall thickness and wall thickness variation.

The process is widely used in packaging of consumer products and to fabricate large items such as bathtubs contoured skylights and internal door liners for refrigerators. Evacuation of the air between the sheet and the mold is required. The 14th International Conference on Axiomatic Design ICAD 2021.

A JOURNAL OF THE THERMOFORMING DIVISION OF THE SOCIETY OF PLASTICS ENGINEERS FIRST QUARTER 2014 n VOLUME 33 n NUMBER 1 Plug-Assisted Thermoforming for Medical Packaging pages 8-10 Composite Material Properties in Laminations pages 14-18 Global Dispatches. 15 x 5 mm. Through the mold flow simulation we can not only optimize the mold flow.

The mold come together and heat seal the two sheets together where the molds meet. Design for holes and trim lines 30 Cost - Thermoforming Initial Cost Equipment cost is low to moderate but can be high if automated Tooling cost is low to moderate depending on the complexity Variable Cost Labor cost is low to moderate Moderate to low material utilization. Vacuum Thermoforming Process Design Guidelines 1 Materials.

PTI will default to ABS unless specified differently. Several experienced outside mold makers with whom we have worked for many years.

Plans For Building A Table Top Hobby Vac Vacuum Forming Machine Vacuum Forming Vacuum Diy Molding

Dfmpro For Thermoforming Process Dfmpro Blog

Thermoforming An Overview Sciencedirect Topics

Download Free Vacuum Former Plans Screen Printing Machine Vacuum Hobby Kits

Representation Of A Thermoforming Process The Mold Object Of This Download Scientific Diagram

China China Oem Thermoforming Mold Design Quotes Plastic Injection Molds Mestech Manufacturer And Supplier Mestech

0 comments

Post a Comment